Sanyo♪ Tri-Yong-Yong ♪ PELECTRON PVL

Promise to only make original

Log in to view quotes

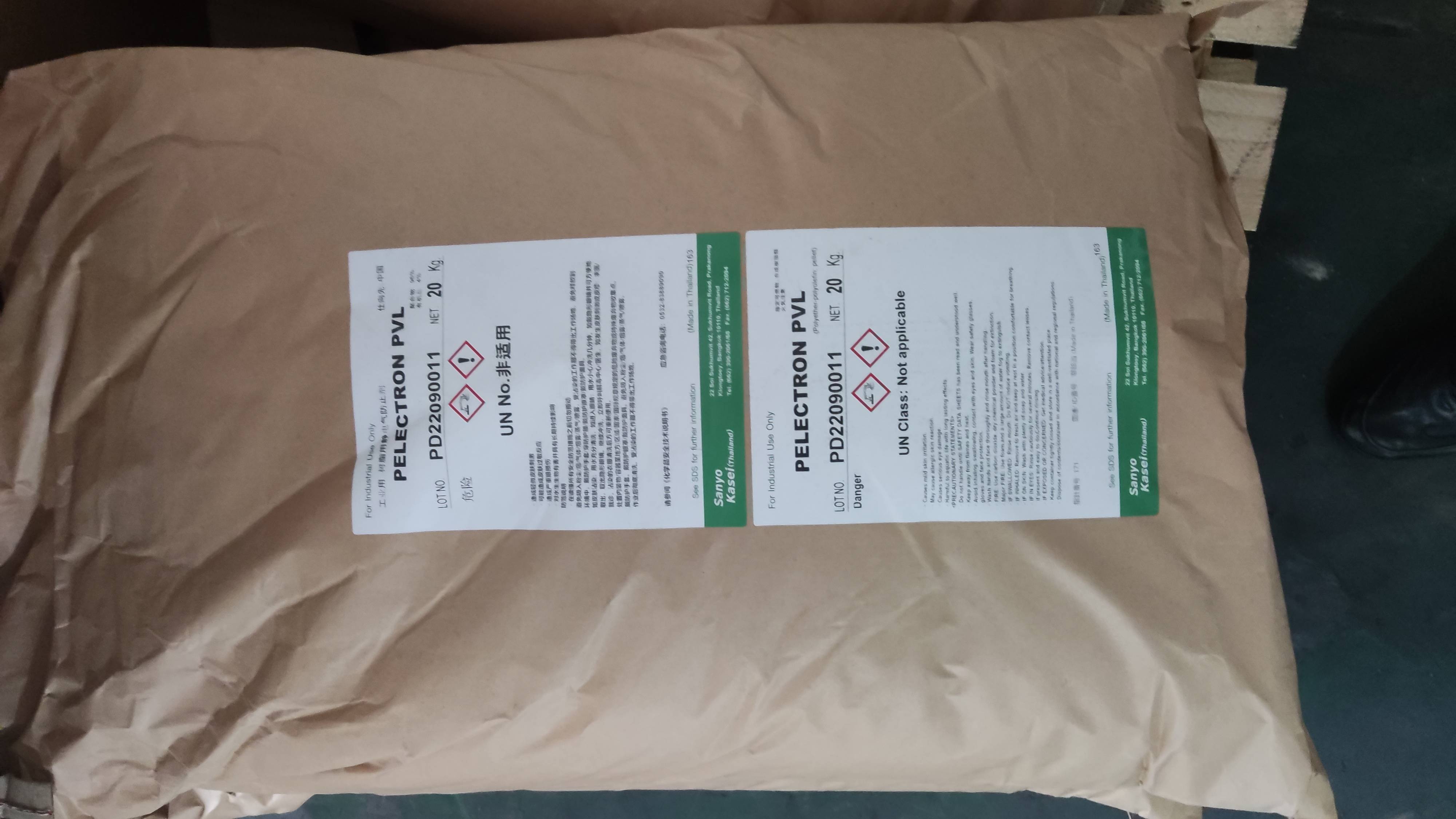

Spec: 20.000kilograms/Bag.

Region: Japan

Monthly sales: 2100.000kilograms

Levels of danger: No.0Classes Non-hazardous goods

Stock in: -

Last transaction:

Collection popularity0

Brand infoPELECTRON

ModelPVL

CategoryOther antistats.

Brand: ♪ Tri-Yong-Yong ♪

Model:PELECTRON PVL

Product characteristics:It's good to be dispersed.、Few additions、Antistatic effects10It's... it's... it's... it's... it's... it's... it's... it's... it's... it's... it's... it's... it's... it's... it's...8Subherent and lasting.

Packaging specifications:20kg/Bag.

Apply:ABS,HIPS,PC/1BS,PP,LDPE......

PELECTRON PVL It's a herna resin developed using the company's own decentralized technology.(Polyethylene resin、Polypropylene resin, etc.)Use continuous antistats.。

Because of its excellent dispersion of acetylene resins.,So usually you mix it with the dry resin and you can form it.,The ability to give semi-continuing static electrostatic properties to resins with little change in their physical properties and formation.。And...,Compared to previous continuing antistats,Significant reduction in the resistance value inherent in the surface,So it's just a small addition that's going to have an excellent electrostatic effect.。

Out View : Pale-coloured little spherical

Melt Points : Date of receipt of the relevant documents. 135℃

MFR : Date of receipt of the relevant documents. 15g(10min)[ASTM D 1238(190℃、21.18N)]

Inherent Retardation Values on the surface : Date of receipt of the relevant documents. 3×106

Ω(ASTM D 257)

Endurance. Hot. Sex

Thermal reduction starts at the temperature. : Date of receipt of the relevant documents. 250 ℃ [JIS K 7120(TG-DTA France,In the air.)

PELECTRON PVL Having the following characteristics:。

1.For acetylene-based resins,Could not close temporary folder: %s 5~20 Quality%,From dust prevention to protection of electronic parts and circuits

The area of electrostatic diffusion,It gives them excellent electrostatic protection.。

2.In film and panels for polyethylene resins and polypropylene resins,Almost no harm to the physical properties of these resins.,I'll give it to you.

Give it an excellent electrostatic protection.。

3. Because it's a high-molecular electrostatic preservative.,So the effect is semi-continuing from the moment it's formed.,Even the washing of water has hardly changed.。And it's less dependent on humidity.,Even at low humidity, it can play an electrostatic role.。

4.Because it's good at dispersing acetylene resins.,So usually, you don't have to build them in advance.,It can be mixed with the stem of the resin.,There's no need to use dispersants or anything.

1. PELECTRON PVL General methods of use

Please add the acetylene resin and PELECTRON PVL It's a mixer. It's a mixer.,Use of various shapers, such as a plasticizer, for the particle(Small Sphere)It's done. It's done. It's done, it's done, it's done, it's done, it's done, it's done, it's done, it's done, it's done, it's done, it's done, it's done, it's done, it's done, it's done, it's done, it's done, it's done, it's done, it's done, it's done, it's done, it's done, it's done, it's done, it's done, it's done, it's done, it's done, it's done, it's done, it's done, it's done, it's done, it's done, it's done, it's done, it's done.。Please add fillings and paints during dry mixing, as required.。

The ball is well shaped using a variety of shapers, such as squeezing machines.。

2. Add Amount

PELECTRON PVL The standard addition is usually a resin. 5~20%。

Please refer to performance test.,Set good additions according to purpose of use。

3. Refrigerator and Melting Conditions

When there's a need to melt.,Please use a double-axis squeezer, a blender with a high refining capacity.。It's usually about the temperature of the molten mix. 180~230℃。Please refer to performance test.,Good temperature by resin type。

4. Use after opening

PELECTRON PVL It's a wetproof package after dry treatment.,So it's usually used directly.。But...,Because it's soaking wet.,So...,When placed under open seal,And when there's bubbles when you're in shape.,Please refer to the following conditions for drying before using them.。And...,♪ In shape ♪,Recommend the use of dry dryers and dehumidifiers(If PELECTRON PVL The moisture of the mixture with the form resin exceeds that of the mixture. 500ppm,There's a risk that the bubble will cause a bad look at the shape.)。

<Dry condition cases>

(1) Depressive dryer.

Less Press. degrees : 1,300Pa Below

Warm. degrees : 70℃~80℃

Hour Time. : 2~4 Hours

(2) A resin dryer.(Hot wind dry.)

Warm. degrees : 85℃~95℃

Hour Time. : 4~6 Hours

(3) Attention to prevent misuse

Yes. 170℃For use at the following morphological temperature: PELECTRON PVL Hour,If it doesn't melt, it won't be able to fully perform.。

And...,♪ Over and over ♪ 240℃to be used at the temperature of the formation,And it could cause thermal decomposition when it's formed.,I can't fully perform.。And...,Numerical temperature is recommended as 170~230℃。

Depending on the range of resins,,It may also have adverse effects on the physical properties of resins, such as mechanical performance.。Please confirm in advance the effect on the physical properties of the resin.,Use in unproblematic terms。

PELECTRONSeries | |||||

Parameters | PELECTRON HS | PELECTRON AS | PELECTRON PVL | PELECTRON PVH | PELECTRON UC |

Melting Point(℃) | 135 | 195 | 135 | 135 | 150 |

Melting Index(g/10min) | 10(190℃,21.18n) | 30(215℃,21.18n) | 15(190℃,21.18n) | 7(190℃,21.18n) | 12(190℃,21.18n) |

Refraction rate | 1.5 | 1.51 | 1.50 | 1.50 | 1.50 |

Temperature of thermal degradation(℃) | 240 | 285 | 250 | 250 | 250 |

Surface resistance rate(Ω/sq) | 4*106 | 4*106 | 3*106 | 2*106 | 5*106 |

Apply modeling methods | Shapes | Shapes | |||